Vibration Isolation of Extract Fan at Bowsher

We were approached by the residents on the top floor of a building in Bowsher to address an issue of vibration from an extract fan installed on the roof. This fan was installed to remove smoke from a grill restaurant in the ground floor.

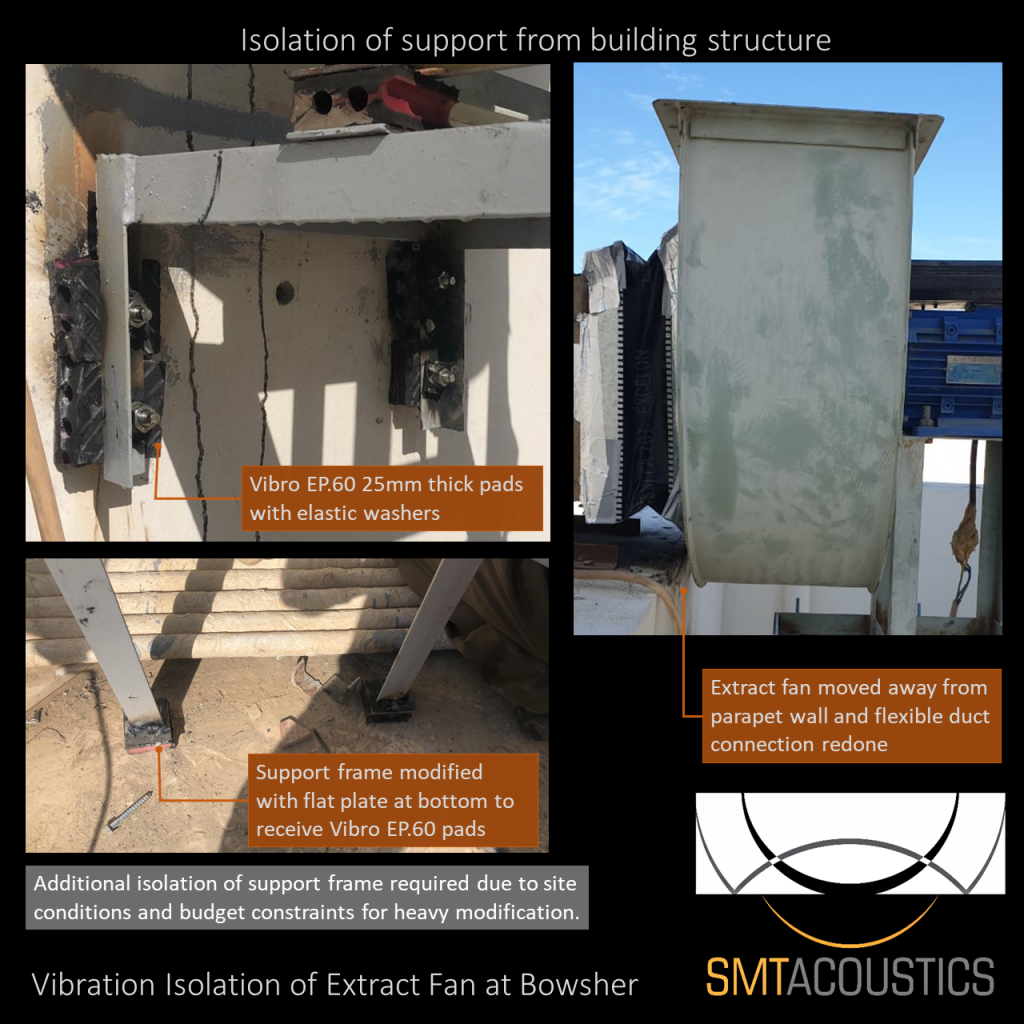

The extract fan was installed on a metal stand which was fixed to the floor and parapet wall, passing down the vibration which spreads through the entire structure of the building. But the impact was strongest on the floor just below.

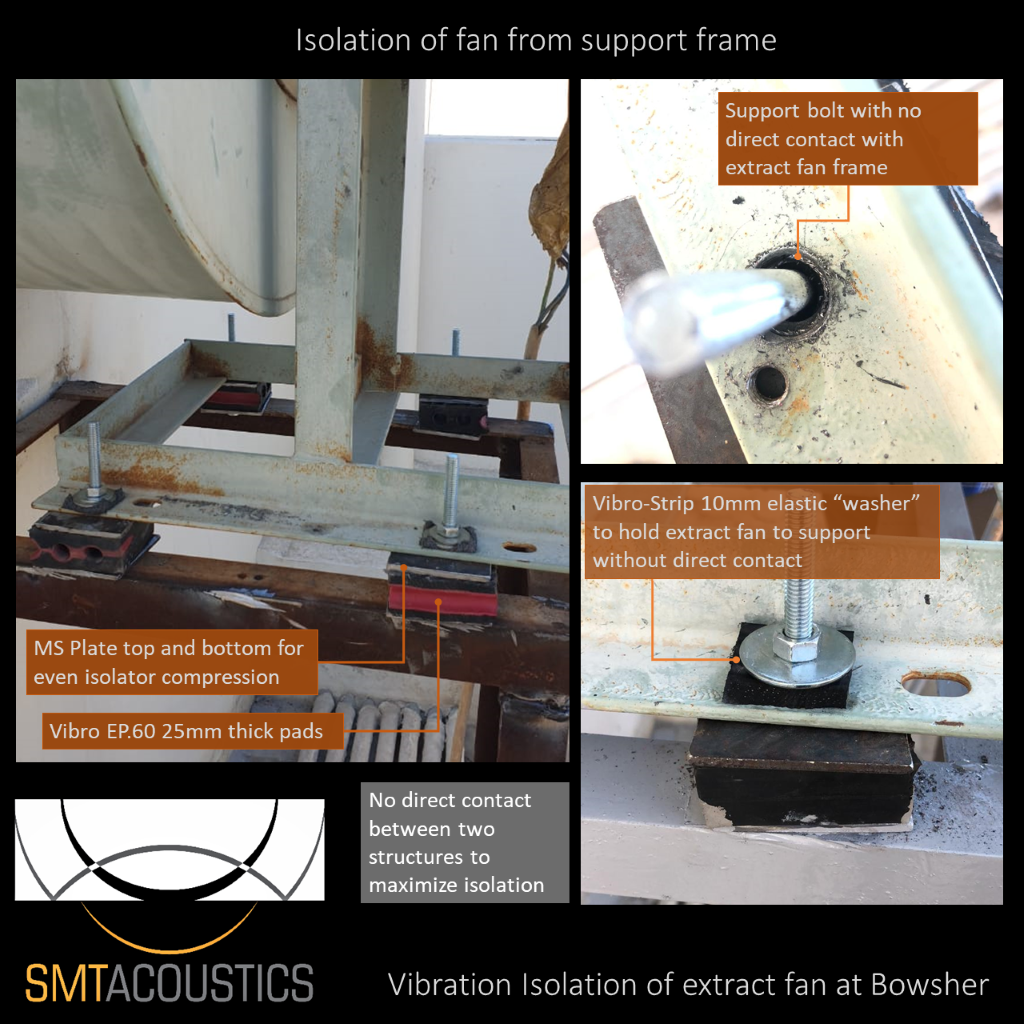

We addressed this issue by adding installing Vibro EP 6cm x 6cm x 2.5cm vibration isolation blocks between the metal structure and the fan and the rest of the building structure. We added a 2mm steel sheet above and below our pad to distribute to load to the entire block.

To ensure structural stability, the whole structure was held in place through bolts, which were again “isolated” with a rubber washer we cut out of Vibro Strip isolation pads, which is an extremely versatile product that can be used in variety of structural isolation applications.

After installation of these solutions, the tenants in the floor directly below were very happy and there was a very noticeable and significant reduction in vibration from the extract fan. While an ideal installation with open springs with 25mm deflection would have had an even higher performance, this would have been a much more expensive job which would not have suited the restaurant’s budget.

Almost all of the equipment that is generally installed on the roof work at the 50Hz or 3000RPM rate, which includes compressors, pumps and even fans such as the extract fan in this project. When it is only a few of machines installed on your roof, the vibrations would be barely noticeable, and mainly it would not be audible and below our threshold of human hearing.

But in a 7 or 8 floor building with 6 flats or rentable units per floor and 3 to 4 AC units per flat, these vibrations add up and there are higher chances of it being clearly audible throughout the entire building! Especially given most rooms have 2.8-3.5m height this would mean the primary axial “mode” for your room falls within the 45 to 60 Hz range, which would amplify this vibration and bring it to the audible range and they would be of “tonal” nature.

By tonal noise we mean 1 particular 1:3 octave bands stands out more than a certain threshold compared to its neighboring 1:3 Octave band. For 25-125Hz band, this 15dB in our instrument. This would be clearly audible for you like a humming sound. For higher frequencies, this threshold is much lower. By ensuring we reduce the measurable noise level in the rooms below from the machine to “blend” with the rest of the low frequency energy, we can reduce the direct impact from the vibration.

A great learning experience for us to try out working with Vibro EP products in the market. Additionally our first experience of satisfaction from relieving a client from vibration related noise!